Less Common Metals Ltd is a world leader in the manufacture and supply of rare earth metal alloys to key industries such as the renewable energy sector. For example, our NdFeB alloys are manufactured into permanent magnets and used for various applications such as wind turbines and electric vehicles. As such, we are aware of the need to ensure that we effectively manage and minimise the environmental risks associated with our processes. To this end, we are accredited to the international environmental standard (ISO 14001).

One of LCM’s principal products is samarium cobalt, in various alloy forms, which is produced by heating the raw materials in a vacuum induction furnace at high temperatures. These alloys are used to make high-performance magnets that form components in the manufacture of a range of technologies, such as sensors and very high-speed motors.

One of LCM’s processes for manufacturing samarium cobalt involves the washing of the alloy to remove by-products. Historically, we have used rainwater collected on-site for this washing process, as well as for diluting the resulting liquid effluent.

Previously this diluted wastewater was discharged to the main drainage system under discharge consent from United Utilities. It was then directed to the Wastewater Treatment Works at Ellesmere Port, operated by United Utilities. Regular monitoring was undertaken at the point of discharge from the factory to ensure that levels of metal compounds such as copper and cobalt were within the environmental quality standard levels prescribed within our water consent.

In 2017 the EU revised and updated its best practice guidance for industries operating within the non-ferrous metal sector. This guidance led to new requirements from the Environment Agency to significantly reduce the levels of cobalt, copper, and iron in our effluent discharge, and these were incorporated into our existing environmental permit.

In order to meet the challenge posed by these new limits, we had to completely rethink our effluent treatment process. This required us to bring in specialist water treatment contractors to devise a novel treatment process for our wastewater. Due to the unique nature of the process, this led us to perform extensive trials, and in-house testing, to find an appropriate chemical treatment to effectively remove all cobalt, and other metal ions, down to levels of less than 5 parts per million. We also had to ensure that the wastewater discharge has a neutral pH (of 7), the same as it is for pure water.

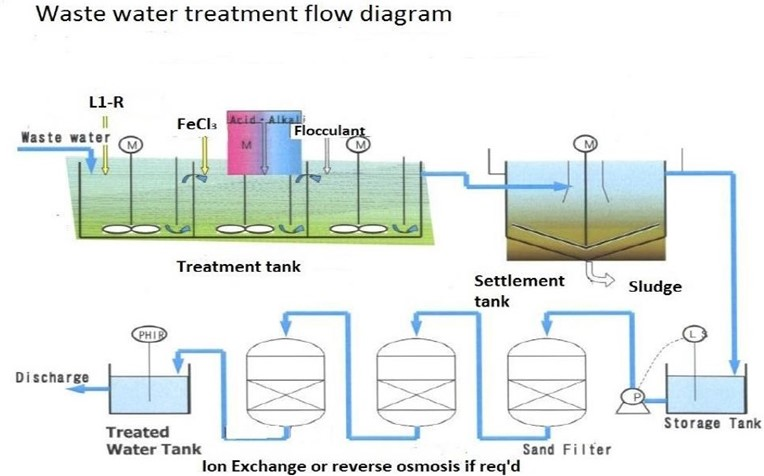

In choosing the appropriate technology we were informed by the latest technical guidance notes, issued by the Environment Agency, which outlines what is described as ‘best available techniques’ (or BAT) for our sector. This suggested a technology consisting of neutralization and organic-based precipitation for the process of water. Consequently, we have now made a significant capital investment and installed equipment comprising of a series of settling tanks, filters and ion exchange columns through which process water flows. It is sequentially treated by the various technologies to neutralize the liquid and filter out all the metal contaminants to produce wastewater of sufficient purity to discharge to the mains sewer.

The effluent is monitored at various stages through the treatment process for pH, flow and conductivity (an indication of the presence of contaminant metals). If the pH or conductivity values are outside specified limits, the effluent is pumped back to a holding tank for re-treatment. The treatment process also produces a solid filter cake that contains metals such as cobalt, and we are currently assessing the options for selling this for the onward recycling of the valuable metals to close the recycling loop.