As a partner of the new PASSENGER project Less Common Metals (LCM) participated in the kick-off meeting on 11th May 2021. The project aims to develop innovative pilot plants to address high economical, technological, social, and environmental relevance: a solution for the EU dependency on rare-earth raw materials for permanent magnets, avoiding bottlenecks in the material supply chain, and diminishing the environmental impact.

Funded by the European Commission’s Horizon 2020 Framework Programme, a total of €8.9m will assist the development and innovative research. With the consortium comprising of20 partners (14 companies) from eight European countries, the project’s applications in e-mobility will have a huge contribution to the EU Green Deal objectives of zero emissions and clean urban transportation.

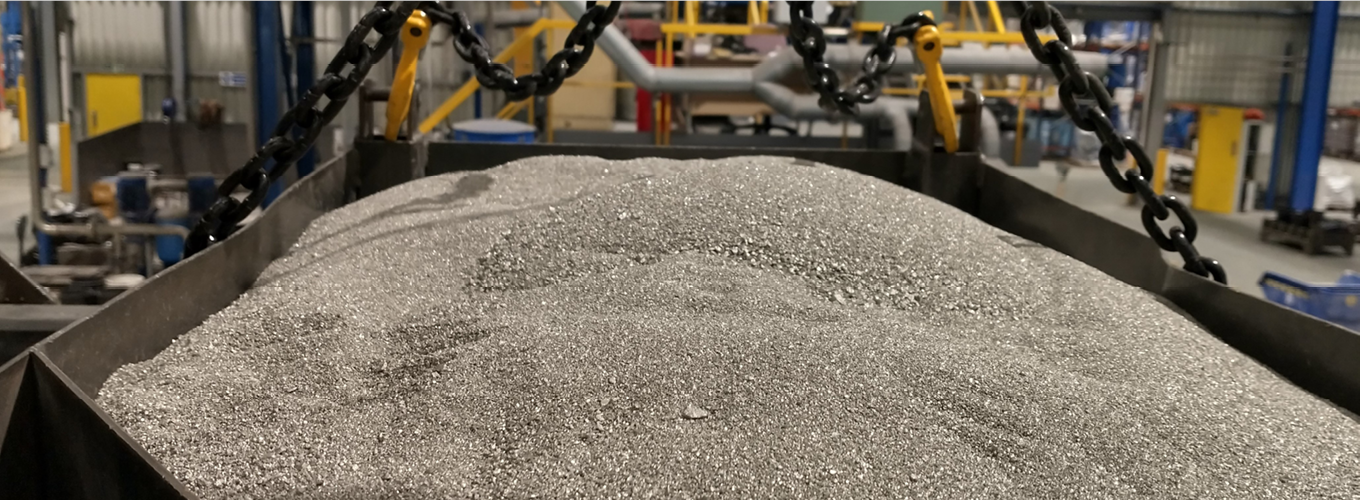

Kagya Nyanin, Technical Manager at LCM gave a presentation on the company’s role in the consortium. As a world leader in the manufacture of rare earth-based alloys and other vacuum induction melted alloys, LCM will up-scale the production of alloys developed in the consortium in an industrial environment. This will include casting, crushing, and milling of alloys to close compositional tolerances, microstructure, and particle size for permanent magnets.

PASSENGER will secure a sustainable industrial solution to Europe’s strategic dependence on diverse raw materials, critical in technological development. The project is funded by the European Union from the climate action, environment, resource efficiency and raw materials work program. Nowadays the lack of sustainable access to several critical raw materials is one of the most serious challenges faced by the European Raw Materials sector. Permanent magnets are one of the most vulnerable categories. These magnets are critical components in technologies that are crucial to Europe’s energy and transport sustainability such as, electric vehicles, wind turbines, aerospace, medical equipment, and a multitude of domestic appliances.

The multidisciplinary PASSENGER consortium consists of 20 partners including key end-users and SMEs/LEs (14 companies) from 8 EU countries: Spain, Austria, Italy, Slovenia, Germany, France, Greece, and United Kingdom. It involves major European industries, academic leaders, and associations occupied with permanent magnet manufacturing, alloy production, powder fabrication, electric motors, e-vehicles, eco-design, and product/process standardisation. Thus, PASSENGER covers the whole magnets production value chain, from studying fundamental properties to the production of high-technology end products, while aiming at making the transition from a linear to a circular model involving citizens, international platforms, and relevant stakeholders. This unique combination of expertise and approaches can guarantee the successful delivery of this very ambitious work program.