As one of 19 partners in a €12m project to develop a recycling supply chain for rare earth permanent magnets in the EU, we wanted to update you on our activities. This Horizon 2020-funded project kicked off in 2019 and we are now mid-way through the development.

LCM is responsible for two parts of the project. The first is to recast the recycled NdFeB powders produced from the Hydrogen-based Processing of Magnet Scrap (HPMS) and large sintered NdFeB blocks extracted from end-of-life wind turbines.

The other part is to provide a chemical composition and impurity analysis at the onsite analytical laboratory in Ellesmere Port. This will be done by ICP-OES (Inductively coupled plasma optical emission spectrometry) and Combustion and Inert Gas Fusion techniques for all of the materials within the project.

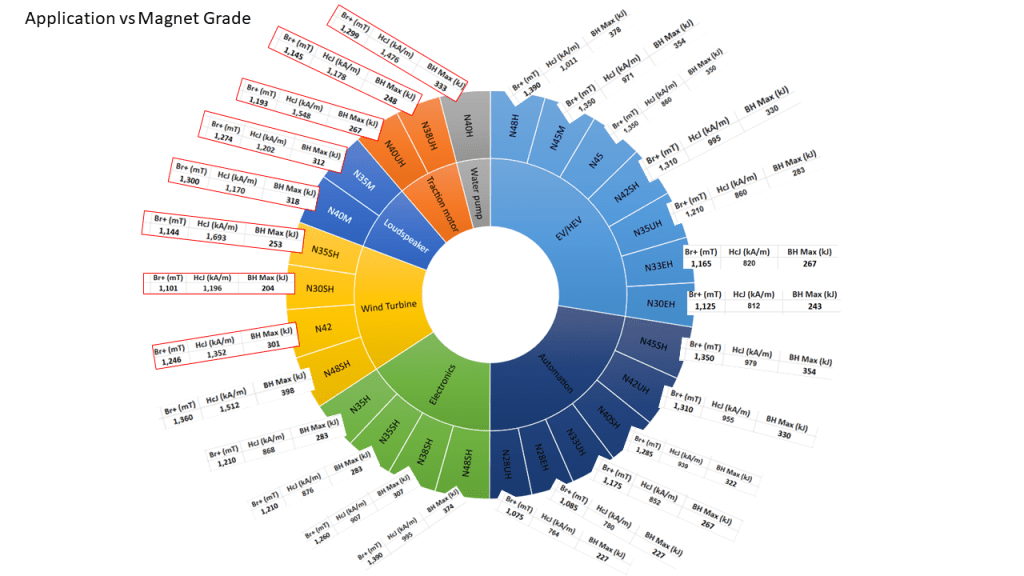

Most recently, we have taken on various magnetic materials to analyse in our laboratory, which has helped to build a visual representation of composition and magnetic properties versus application, as well as a research report on re-casting trials including composition and impurity levels.

Furthermore, our technical staff is planning the re-casting of uncoated magnets and the production of cast alloys with a specific content structure from recycled sintered magnets for the deliverables in the upcoming year.

This will help our project partners in visualising and building a recycling supply chain, with the demand for rare earth permanent magnets (mainly NdFeB) increasing due to the requirements for clean technologies.

The objectives of the project are grouped into four categories: technical, economic, environmental, and social. Within each of these objectives’ partners at SUSMAGPRO will work together in delivering a sustainable future for the RE supply chain, addressing various of the UN’s Sustainable Development Goals.

Figure 1: Map of composition and magnetic properties vs. application

Composition and magnetic properties vs application